Code: 24091230

Table with folding mechanism 24091230423.92 Eur without VAT

(512.94 Eur with VAT)

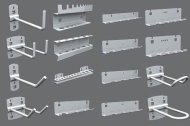

Table with folding mechanism made from a tubular modular system. The table includes a folding structure for securing trash bags, an 18 mm thick laminated worktop, two shelves with 10 mm thick Akyboard, four swivel wheels with brakes, each with a diameter of 100 mm, and a perforated panel for hanging tools or storage bins. The shelf load capacity is 50 kg, the worktop load capacity is 100 kg, and the total load capacity is 200 kg. Dimensions 1335 x 1029 x 498 mm, dimensions after folding the holder 1335 x 1595 x 498 mm.