Code: perfo_1117_1000_ESD

ESD perforated panel with holes for mounting71.18 Eur without VAT

(86.13 Eur with VAT)

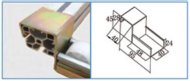

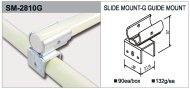

ESD perforated panel with rounded edges. Holes for mounting in a tubular system or on the wall. Ideal for hanging tool holders and for quick access to fasteners. The ESD design provides reliable protection against electrostatic discharge. Dimensions 1117 x 1000 mm, thickness 1.4 mm, square holes 10 x 10 mm, hole spacing 38 x 38 mm, color gray RAL 7035.